The Spring Festival is approaching. To comprehensively identify and eliminate all potential safety hazards, and to ensure the smooth and safe operation of all logistics links during the festival period, Jiusen Logistics Group Co., Ltd. (hereinafter referred to as "Jiusen Group") recently coordinated and organized its subsidiaries to conduct a three-day pre-festival safety joint inspection.

This inspection focused on key aspects such as special equipment management, on-site standardized operations, proper placement of containers, and water and electricity safety for outsourced units. Through systematic hazard identification and closed-loop rectification, it significantly enhanced the overall safety management level of the group, providing a solid safety barrier for logistics services during the holiday period for customers, and ensuring the continuous reliability of supply chain services.

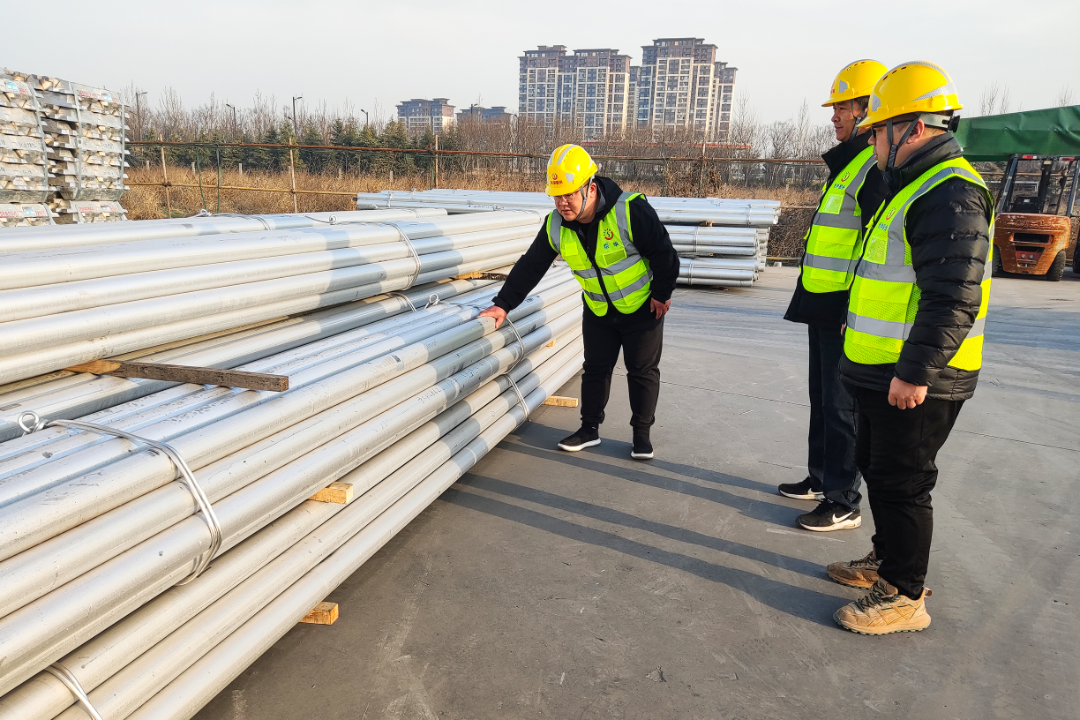

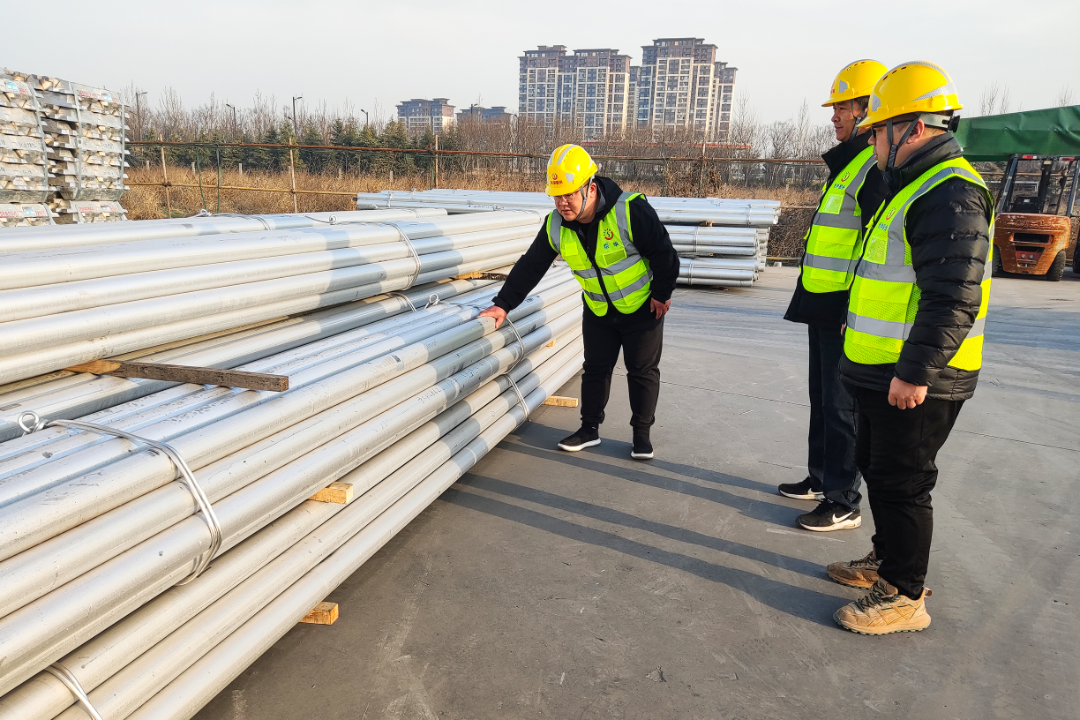

The inspection team went deep into the work site.

This safety comprehensive inspection was uniformly deployed by the group headquarters. Each regional subsidiary cooperated and coordinated to form a special inspection team. The inspection team conducted in-depth inspections at the operation sites, storage areas, and the locations of cooperating units. Through various methods such as on-site investigation, data verification, and personnel interviews, they carried out comprehensive and meticulous hazard inspections.

In terms of special equipment management, the focus is on verifying the regular inspection reports, daily maintenance records, and the certification of operation personnel for equipment such as container handlers and forklifts, ensuring that the equipment operates in compliance and that personnel operate with certification. During on-site operations, particular attention is paid to checking the standardization of operation procedures, the clarity of safety signs, and the smoothness of fire escape routes, to lay a solid foundation for on-site operation safety. For container storage yards, strict inspections are conducted on the neatness and stability of container stacking, ensuring that the spacing between stacks and the stacking height comply with safety standards. At the same time, a comprehensive investigation is carried out on the entire process of water, electricity, and gas management for outsourced cooperation units, urging them to strictly implement safety management regulations and tighten the safety valves in cooperation links.

In order to precisely meet the customer supply chain service demands during the Spring Festival and minimize the occurrence and impact of all kinds of emergencies, each subsidiary of Jushen Group made adequate preparations and implemented effective measures throughout the entire inspection process. For the problems identified during the inspection, they insisted on immediate investigation and immediate correction. A detailed problem rectification ledger was established, specifying the person responsible for rectification, the rectification measures, and the completion time limit, to ensure that all potential hazards are effectively rectified and implemented. At the same time, the safety production emergency response plan during the festival period was further supplemented and improved, emergency materials were strengthened and inspected, the personnel duty and standby arrangements were optimized, the duty responsibilities and emergency handling procedures were clarified, to ensure that sudden situations can be responded to and handled efficiently and promptly.

Holidays are crucial periods for ensuring safe production. Therefore, we must tighten the safety production measures and solidify the responsibility chain for safety production. This comprehensive safety joint inspection across the entire system is not only a thorough "safety check" of the group's safety work, enabling timely identification and elimination of safety risks and hazards during the holiday period, but also a practical test and capacity enhancement for the safety management levels of each subsidiary. It further strengthens the safety responsibility awareness of all employees.

In the future, Jushen Group will continue to enhance the safety awareness of all employees, steadily promote the standardization of operation procedures and the normalization of facility and equipment management, integrate safety production requirements into daily work and maintain them consistently, and effectively ensure the safety of personnel and goods as well as the stability of enterprise operations. We will provide our customers with safer, higher-quality and more efficient comprehensive logistics and warehousing services.